We keep asking ourselves — What makes fashion design innovative? Apart from countless recycled textile and pattern designs that we see, love, and forget from each season’s runways, what’s that one thing that could truly make fashion “new” NOWADAYS?

Wearable tech, digital fashion, NFTs and a bunch of other new terms are circulating in the fashion industry. But what is one thing that truly has the potential to change the whole infrastructure of the fashion industry while linking all the above-mentioned new trends?

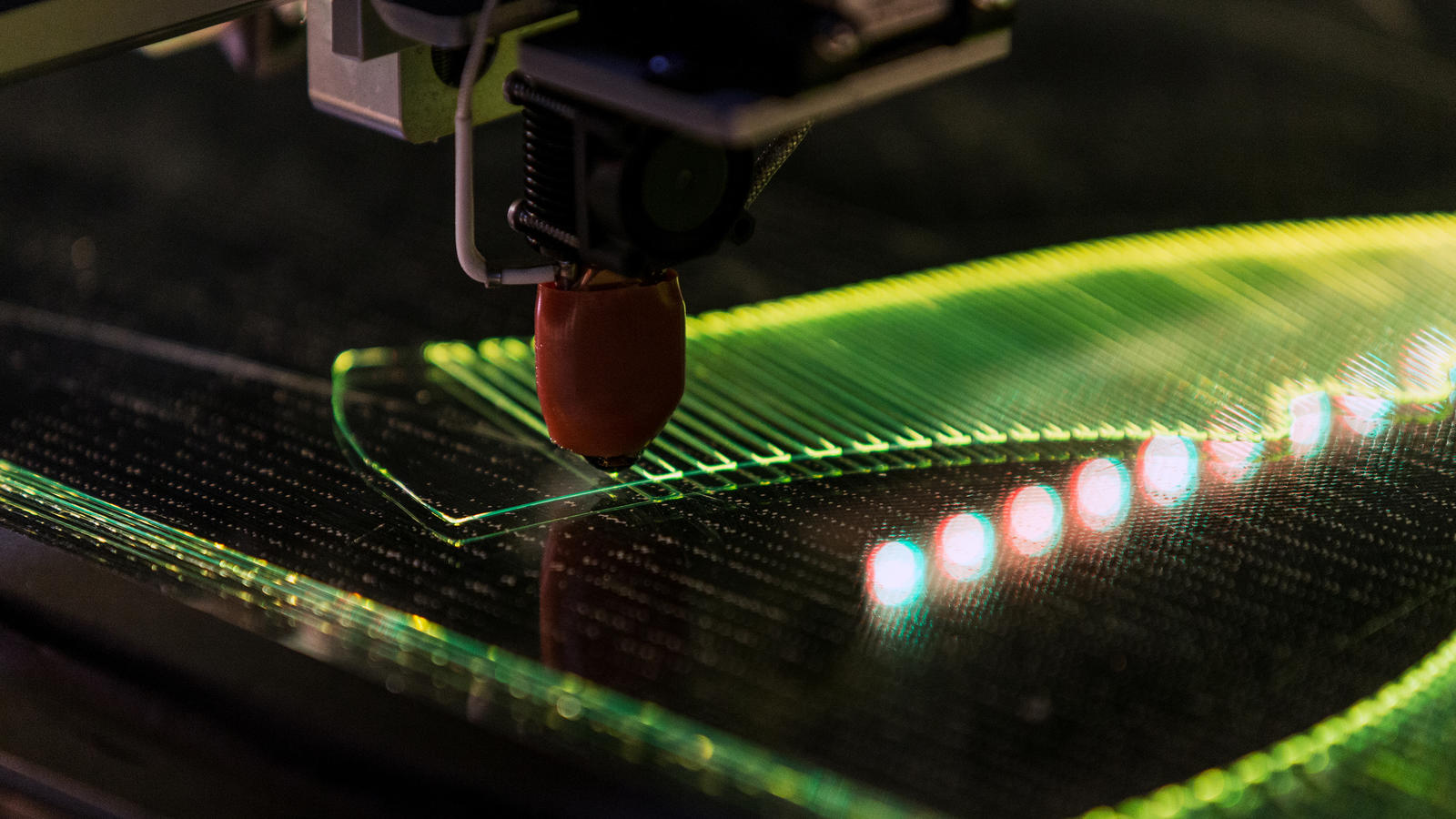

3D printing in fashion might be the under-appreciated technology that unlocks new experiences for both designers, fashion makers and most importantly — fashion consumers like you and I.

The next era of the fashion industry

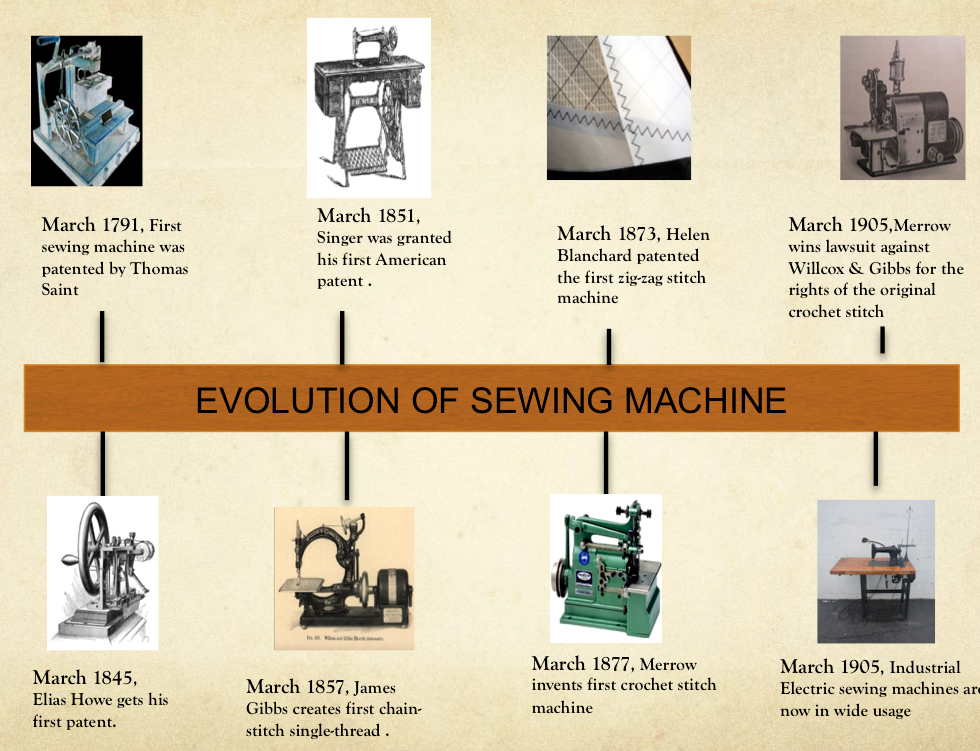

If we think about the days before the Industrial Age, fashion was made mainly by tailors, and you’d probably change your clothing less frequently due to the economic status of the time and slow productions.

Clothing mass production started in the mid-19th century, when several factories began to make clothes that did not require tailoring, but fashion did not become an existing industry in the institutional context of the world until the 20th century. The start of fast fashion culture has provided us the freedom to experiment different styles for more affordable pricing and enabled fashion creatives to think more about the design rather than making.

Fast forward to now, the introduction of 3D printing technology to the fashion industry can be viewed as the next fundamental change to fashion R&D. From the designing process to the raw materials we use, and to the printing & curing process — everything differs from how we produce clothes now. So, how could a piece of printer could redefine the whole industry?

A world with 3D printed wearables

What if 3D printed wearables becomes ubiquitous? What do we get as fashion consumers? Well, we would get more “actual” new designs. New 3D manipulated designs, new structures, new filament innovations…etc. The possibilities of new materials that we can develop for each stage of the process is countless.

If we think a step further, you will be able to print clothing at home, on demand. You would be able to purchase digital fashion files from online and print whenever you want. Which means if 3D printers are just as common as traditional ink-on-paper printers, it will help empower the digital fashion, fashion NFTs communities as their designs will have an additional outlet other than being used digitally only.

In short, 3D printers could bridge the gap between digital fashion creators and consumers who love sustainable, on-demand, and truly unseen fashion designs. No more delayed deliveries, no more waiting in lines to try out new clothing. From the minute you enter the (online) shop to you picking out and trying on clothes, to you purchasing and receiving, everything will be digital.

Pros & cons of 3d printing in fashion for designers

Benefits of 3D printed fashion

- Availability: With 3D printing, it is far less hassle to create clothes on demand. Designer clothing is expensive because it is made to fit your body, and it takes time to produce in an atelier. A 3D printed design is cheaper and quickly made available. With 3D printing, prototypes can be created quickly and hence can allow for faster availability of clothes.

- Sustainability: Additive manufacturing also reduces waste as it directly adds the material to the source eradicating the waste that is a usual outcome of fabric processing and design. For example, in a conventional manufacturing process designers have to cut and shape the materials that lead to fabric cut-offs and scraps. Additionally, conventional fabric manufacturing uses dyes that lead to water pollution, and factory smoke produced during the process pollutes the air. With additive manufacturing this pollution is reduced drastically.

- Agile production: 3D printed fashion allows designers to innovate faster. It helps save time by avoiding the need to order prototypes from third-party suppliers. With 3D printing prototypes can be created quickly with CAD software regardless of the complexity of the design. This moves the product faster to its finish line and gives designers a chance to do more with their time and money.

Pitfalls of 3D printing in fashion

There is always a downside to new technologies, 3D printing in fashion is no different either.

- Immature technology: The technology is still very young in the fashion space. There is still so much to explore in terms of curing and mass production.

- Copyright: Similar to music and movie piracy, design file piracy can also affect the fashion industry. However, with the rise of NFTs and digital asset copyright laws, this matter may have a resolution soon.

- A new economic model: Loss of manufacturing jobs in the fashion manufacturing industry is also something that could be connected to the rise of 3D printing. While some manufacturing jobs will be lost, a new array of jobs will be open. With people printing clothes in their homes and companies making small batch sizes for specific collections, the business model of large factories churning out container loads of fashion items could be a thing of the past. So, the replacement of cheap human labor with machines could lead to job losses in certain parts of the world.

- Quality control: If people are going to print their personal items at home, this may impact the quality of the designs.

New lingo of the future fashion industry

Imagine that you have an idea for an amazing dress in the middle of the night. A conventional designer would grab paper and pen to draft patterns, and then pin the patterns on top of flattened fabrics, lastly we sew them together. Now all that is going to change. What are the new terms that we should familiarize ourselves with?

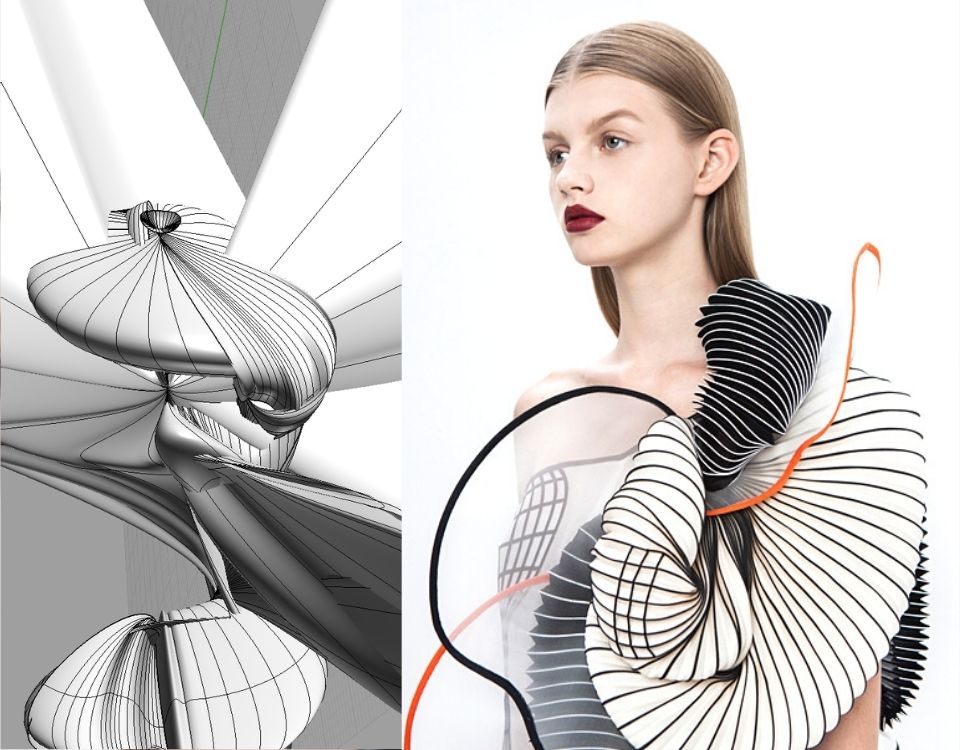

Hand Sketches → 3D Modelling + Rendering

Any 3D printing process involves both 3D modelling and rendering. 3D modelling involves designing a detailed illustration of an object. 3D rendering, on the other hand, is the process of creating 2D images from 3D illustrated models.

A 3D modelled object is depicted in a 3D space with defined edges and an overall shape. This allows designers to see if the design is possible physically. Additionally, the process helps designers smooth out any design issues that are impossible to see in hand sketches. Some designs only look good on paper and are impossible to execute physically. 3D modelling allows designers to work out the complications before the design goes into production.

Moreover, a 3D model design can be used for promotions. Designers can upload 3D designs on their website, allowing potential customers to experience the design before they purchase it.

3D modelling and rendering is what hand sketches were 10 years ago. Hand sketches are still very popular and will not likely lose their prominence, but 3D modelling will be pivotal in saving time and money.

Sewing Machine → 3D Printer

A 3D printer is the new sewing machine of this era. The difference is that you can create a 3D object from a 3D model designed in software like CLO, while you go through a cumbersome process of gathering different components like fabrics and accessories, cutting and adjusting when you sew laboriously through a conventional sewing machine. 3D printing is far less complicated and hassle-free. And it doesn’t even produce so much waste.

Fabrics → Filaments

3D printing filaments are thermoplastic feedstock used in 3D printing. Different filaments have different properties and require varying temperatures to make printing possible. A standard 3D printing filament can be found in two diameters: 1.75 and 2.85 mm. Unlike fabrics and accessories, filaments are added to the heating chamber of the extruder assembly where they melt and squirt out through a metal nozzle to create a 3D object, layer by layer.

With fabrics and accessories, a lot of components are needed in order to achieve a certain design. With 3D printing, filaments automatically create clothing based on the 3D model.

Iron/Steamer → UV Light Oven

Digital Light Processing (DLP) in 3D printing uses ultraviolet light to print out 3 dimensional objects. During the process, the 3D model is fed to the printer and then an ultraviolet image of that model is projected onto a liquid, which then goes through photo-polymerization (it hardens as the UV light hits it). As the final step, the liquid is drained leaving the solidified part.

3D printing’s future in stats

3D printed fashion is going to thrive in the coming years. According to Statista, additive manufacturing will have an estimated market size of $30.6 billion by 2028.

3D printing is rising exponentially and some factors behind this growth are aggressive research and development in 3DP (three-dimensional printing) and an increased demand for prototyping applications in various industries including fashion, medicine, and architecture, just to mention a few. Additionally, technologies like Polyjet and multi-jet fusion, SLS, SLA, Binder jetting and SDL are driving the demand for the 3D industry.

3D printed ready-to-wear clothing for everyone

The fashion industry is embracing 3D printing to create regular on-the-shelf retail clothing collections rather than just using the tech to create a single novel design. This will allow the fashion tech industry to not only reduce the environmental damage associated with conventional fabric manufacturing but also improve the overall manufacturing process.

Well-known Brands that uses 3d printing

Nike

Since its inception in 1972, Nike has always been on the forefront of innovation with its shoe performance technologies including the rubber spikes and sole cushioning. Therefore, it shouldn’t come as a surprise that Nike is one of the first apparel and footwear manufacturers to invest in 3D printed fashion. Their Flyprint was the first performance 3D printed upper. Produced through solid deposit modelling (SDM) where TPU filament is unwounded, melted and laid in neat layers. Today, Nike is using 3D technology to create iterations of footwear parts to push the boundaries of innovation both within and outside its company.

Adidas

An estimated 8 tons of plastic waste ends up in our oceans. Adidas took it upon itself to do something about the plastic waste by collaborating with Parley. Priced at around $300, the Adidas’s Futurecraft 3D printed shoes utilize waste from the oceans. The upper-body of the shoes is designed with plastic from the oceans and the midsole is 3D printed with recycled gill nets and polyester. Adidas has previously launched a shoe made entirely of ocean waste.

New Balance

Running shoes usually contain a squishy shock absorbing midsole made out of molded ethylene vinyl acetate (EVA). New Balance decided to switch midsoles in rubber with more resilient material.

A few years ago, New Balance, a running shoe manufacturer, teamed up with Formlabs, a 3D-printing company to create a new type of midsole in running shoes. The result is TripleCell, a technology designed specifically for footbeds with proprietary Photopolymer components known as the Rebound Resin. New Balance relaunched its classic 990 sneaker with the TripleCell heel. The new $185 runner is far more supportive and lighter than its EVA-based predecessor.

Ministry of Supply’s Seamless Jacket

At $250, the Ministry of Supply jacket is 3D printed as a whole, leaving the final product made without seams. The product is custom made for each individual’s body type and size. About 15-30% of the material also gets saved every time this jacket is made because a 3D robotic knitting machine made these jackets.

Emerging talents in 3D printed fashion

Since many fashion and STEM universities like UAL, Parsons and MIT are offering courses about manufacturing innovation, there are a number of emerging brands that showed on the radar recently. They are making 3D printed fashion more acceptable and accessible, rather than only seen on the runways. You can find our favourite emerging 3D printed fashion designers to follow here.

In the coming years, 3D printing will evolve to become more affordable and diversified in its solutions for the fashion tech industry. Next, let’s explore some of the most prominent 3D designers in the fashion industry.